THE WHY

Before I bought my 944 I did a fair amount of research on the net to find out about the things to look out for when purchasing a car of such an age. Amongst some of its well know weaknesses the sunroof lifting mechanism happens to be one of them. There also happens to be TWO versions of the 944 sunroof lifting mechanism, one for the earlier Square Dash model and one for the later Oval Dash model. A lot of the forums and tutorials on the web will often cover the Oval Dash model only which has a habit of stripping the white plastic gears (two gears, one in each lifting arm), and a simple fix for it can be found here. The Square Dash model does NOT have these gears and uses a different method to lift the roof. A good tutorial for fixing both versions exists in the official Porsche Workshop manual (contained in this tutorial) and here at Clarks Garage. I used both of these sources to help understand and fix the sunroof on my Square Dash 944 and have therefore provided more detailed pictures to supplement these existing guides.

THE TASK

You'll need the following:

Philips cross-head screwdriver

Flat-head screwdriver

Cleaning wipes/cloth

Degreaser

THE HOW TO

(Amateur mechanic job time: Approx. 1-3 hours)

Tips for reassembly:

Once all the new parts arrived I cleaned out all 3 drive tubes using pipe cleaners and degreaser, then degreased all the coils themselves. I also cleaned all the accumulated dirt from the drive motor and slide rail too.

I then re-greased the drive tubes and coils as well as the lifting arms themselves.

The next step involved attaching the the new drive dog (white plastic square in photo below) to the new main coil I'd received. Luckily the new coil I received had the modified screw-in connection (upper picture) for the drive dog as opposed the old crimp style version (lower picture) on the broken coil.

Once the drive dog was attached I then threaded the coil into the drive tube in the boot (shown by right-hand orange arrow) so that went all the way back into the car. Left-hand arrow is the power connection for sunroof motor.

The drive dog was then slid into the rail on the motor assembly with the correct length of coil (305mm).

The motor assembly was then mounted back in position

Next I moved back inside the car to assemble the lifting arms and attach them to the transfer box. I made a slight modification the lifting arm boxes by securing them with zip ties after they had been secured together. I did this because the fixing holes on the previous pair had disintegrated where the screws had either been over tightened or the pressure of the arms had made the boxes explode. The zip ties therefore help spread the strain the screws come under.

Now finally, the transfer box is quite a tricky part to piece together with one pair of hands especially as all 3 drive tubes and their coils have to be lined up correctly. To make up for the lack of an extra pair of hands I used a 3 zip ties to hold the two drive tubes (that are attached to the lifting arms) in place in the transfer box before I inserted the drive gear and then finally the main drive tube (in the space shown by the orange arrows).

Once the whole mechanism was assembled and secured it took a bit of trial an error lining the lifting arm boxes up with the insertion point in the roof. This was achieved by packing them out with a few large shilling washers (shown by orange arrow).

The last piece in the jigsaw involved setting the limiter on the microswitches back on the motor assembly (shown by orange arrow).

Before I bought my 944 I did a fair amount of research on the net to find out about the things to look out for when purchasing a car of such an age. Amongst some of its well know weaknesses the sunroof lifting mechanism happens to be one of them. There also happens to be TWO versions of the 944 sunroof lifting mechanism, one for the earlier Square Dash model and one for the later Oval Dash model. A lot of the forums and tutorials on the web will often cover the Oval Dash model only which has a habit of stripping the white plastic gears (two gears, one in each lifting arm), and a simple fix for it can be found here. The Square Dash model does NOT have these gears and uses a different method to lift the roof. A good tutorial for fixing both versions exists in the official Porsche Workshop manual (contained in this tutorial) and here at Clarks Garage. I used both of these sources to help understand and fix the sunroof on my Square Dash 944 and have therefore provided more detailed pictures to supplement these existing guides.

THE TASK

You'll need the following:

Philips cross-head screwdriver

Flat-head screwdriver

Cleaning wipes/cloth

Degreaser

THE HOW TO

(Amateur mechanic job time: Approx. 1-3 hours)

Having taken the complete mechanism apart I discovered several faults on mine, these were as follows:

1. Broken drive dog (Shown further down post)

2. White transfer box mounting holes disintegrating

3. Both black lifting arm boxes mounting holes disintegrating

4. Main drive coil and left lifting arm coil missing several coils where it engages white transfer box

Luckily I managed to source items 2-3 in one 2nd-hand lot on ebay, and item 1. I was easily able to get from Porsche.

Tips for reassembly:

Once all the new parts arrived I cleaned out all 3 drive tubes using pipe cleaners and degreaser, then degreased all the coils themselves. I also cleaned all the accumulated dirt from the drive motor and slide rail too.

I then re-greased the drive tubes and coils as well as the lifting arms themselves.

The next step involved attaching the the new drive dog (white plastic square in photo below) to the new main coil I'd received. Luckily the new coil I received had the modified screw-in connection (upper picture) for the drive dog as opposed the old crimp style version (lower picture) on the broken coil.

Once the drive dog was attached I then threaded the coil into the drive tube in the boot (shown by right-hand orange arrow) so that went all the way back into the car. Left-hand arrow is the power connection for sunroof motor.

The drive dog was then slid into the rail on the motor assembly with the correct length of coil (305mm).

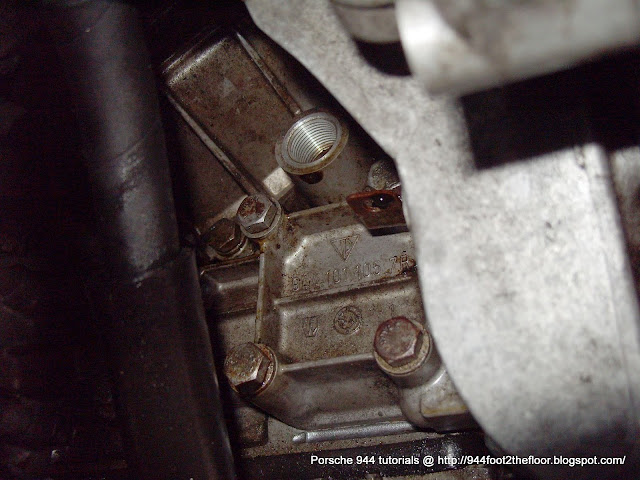

The motor assembly was then mounted back in position

Next I moved back inside the car to assemble the lifting arms and attach them to the transfer box. I made a slight modification the lifting arm boxes by securing them with zip ties after they had been secured together. I did this because the fixing holes on the previous pair had disintegrated where the screws had either been over tightened or the pressure of the arms had made the boxes explode. The zip ties therefore help spread the strain the screws come under.

Now finally, the transfer box is quite a tricky part to piece together with one pair of hands especially as all 3 drive tubes and their coils have to be lined up correctly. To make up for the lack of an extra pair of hands I used a 3 zip ties to hold the two drive tubes (that are attached to the lifting arms) in place in the transfer box before I inserted the drive gear and then finally the main drive tube (in the space shown by the orange arrows).

Once the whole mechanism was assembled and secured it took a bit of trial an error lining the lifting arm boxes up with the insertion point in the roof. This was achieved by packing them out with a few large shilling washers (shown by orange arrow).

The last piece in the jigsaw involved setting the limiter on the microswitches back on the motor assembly (shown by orange arrow).